Hey folks 👋

Today, we’re diving into a familiar topic – plastics. Plastics can cause a lot of harm. We’ve all seen images of sea turtles with plastic straws stuck in their noses, or ducks with plastic beer rings hung around their necks. Plastics endanger wildlife, and us – plastic production is responsible for a significant amount of greenhouse gases (GHGs). In this post, we’ll dive into the sources of plastic pollution, what needs to change, and how we can solve the problem.

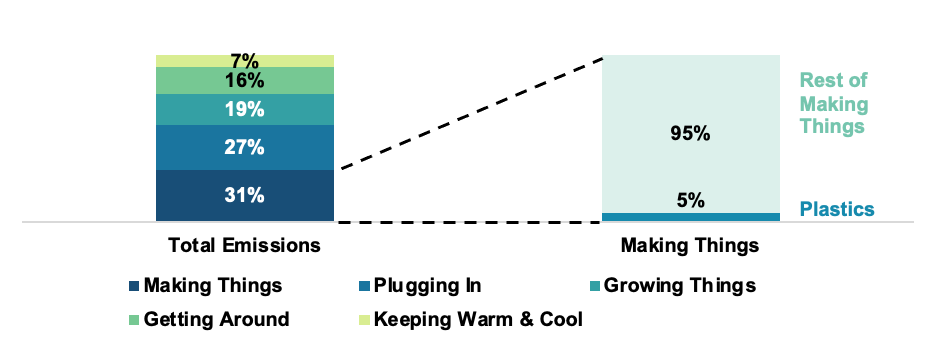

How Much GHGs are Emitted From the Things We Do?

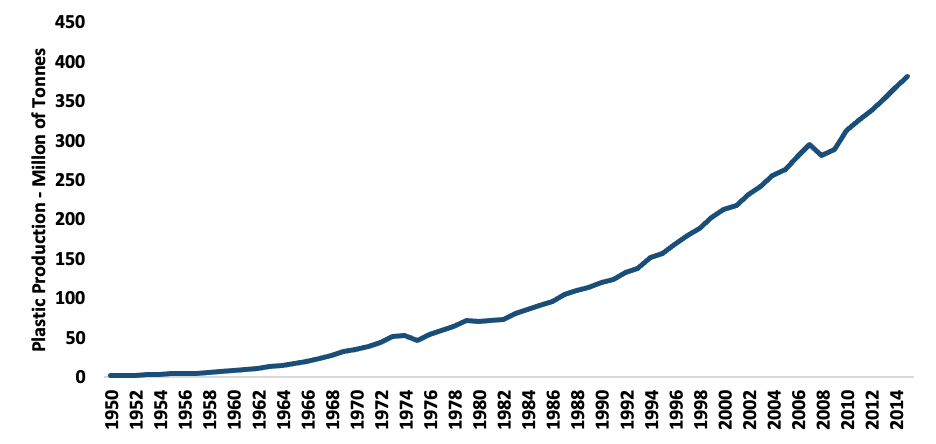

Global Annual Plastic Production

Our global dependence on plastics is relatively new. In 1950, we only produced 2 million tonnes of plastic. By 2019, we produced 460 million tonnes. That’s an 8.2% annual growth rate over the period. While the annual growth rate has slowed to 4.8% between 2015-2019, we need to bring that growth rate to negative territory, and quickly. Based on current projections, we could see more plastic than fish in the world’s oceans if we measure by weight. All that plastic adds over 850 million tons of greenhouse gases per year to our atmosphere. Globally, plastic production accounts for 4-8% of oil demand.

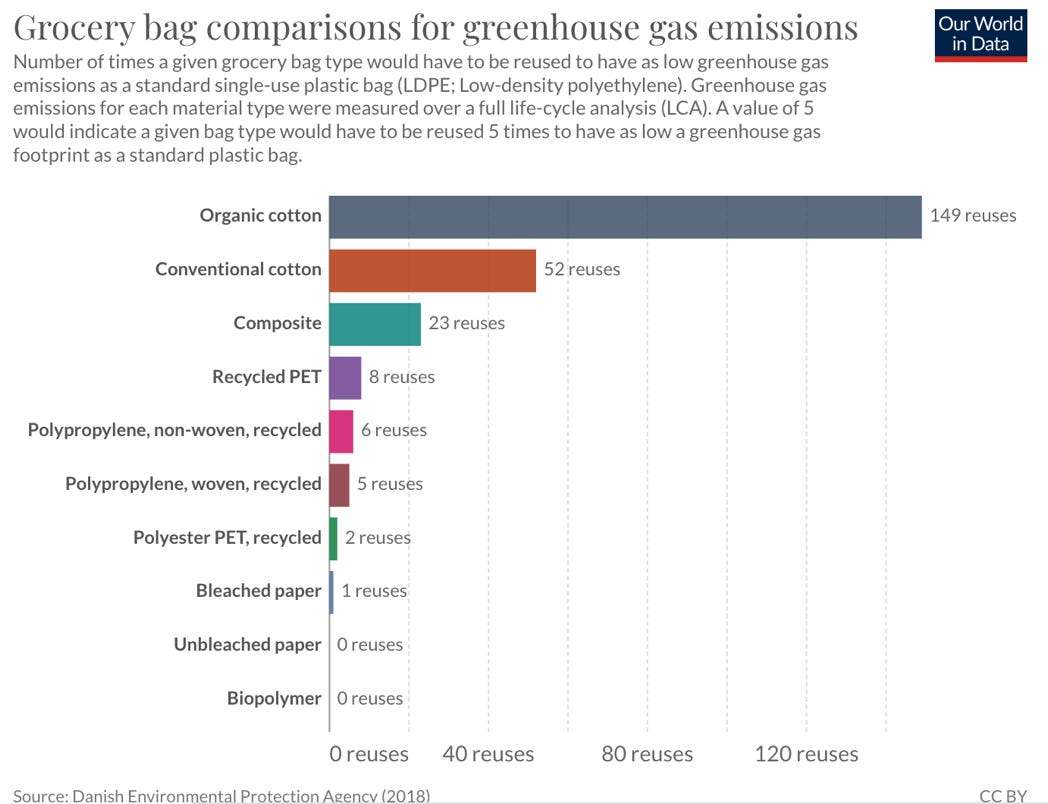

We all know plastics are bad, so why do we use so much of them? Turns out it’s hard to match the strength, weight, and cost of plastics with other materials. The graph below from Our World in Data shows how often different materials must be reused to match the GHG emissions from a single-use plastic bag. This data doesn’t prove that plastics are irreplaceable, but it demonstrates that alternatives are hard to find.

However, solving the plastic problem is very important. According to Christof Ruehl, a senior research scholar at Columbia University, removing single-use plastics can have a bigger impact on oil demand than the impact from electric cars.

Sources of Emissions

Before we jump in, the graph below helps contextualize the global plastics industry – what we use it for, what types we use, where in the world we use it, and where it ends up going.

Nearly all plastics are made from fossil fuels – plastic molecules are derived from oil, gas, and coal. Plastics are commodity chemicals, so it doesn’t matter which fossil fuel is used in production – the plastic comes out the same. Fossil fuel selection is therefore largely driven by cost and availability.

Here’s the process:

National Geographic provides a great video summarizing the plastic production process:

Plastics emit greenhouse gases in every part of their lifecycle: fossil fuel extraction and refinement, manufacturing, and waste management. Different types of plastics emit different amounts of GHGs. Below are estimates of GHG emissions by type of plastic.

Greenhouse Gas Emission Estimates by Type of Plastic

Roughly 50% of plastics’ GHG emissions during production come from electricity. According to Material Economics and CIEL, producing plastic with low- or zero-carbon energy would reduce the GHGs from plastic production by half. The remaining half of GHG emissions are from using fossil fuels as production materials.

Post-Production Plastic Problems

Plastics also emit GHGs after production – the carbon contained in plastics is released into the atmosphere when plastics are incinerated or decomposed. Plastics in landfills release fewer GHGs compared to plastics in incinerators because plastics degrade slowly in landfills. However, landfills pose other risks, including soil contamination. Plastic incineration causes more emissions because the carbon contained in the plastic is directly released when it’s burned.

We sometimes use the energy generated by plastic incineration as an alternative to traditional fossil fuels, which are used for heating industrial processes in paper mills and cement kilns. Mitigating the damage from plastic incineration only makes sense if we have absolutely no other choice but to incinerate the plastic. According to a CIEL report, plastic incineration produces 0.9 Mt of CO2 per Mt of plastic burned above and beyond the 2 Mt of CO2 typically incurred from fossil fuels. Over time, industrial processes will depend less on fossil fuels as we shift towards renewable energy, worsening the net impact of plastic incineration.

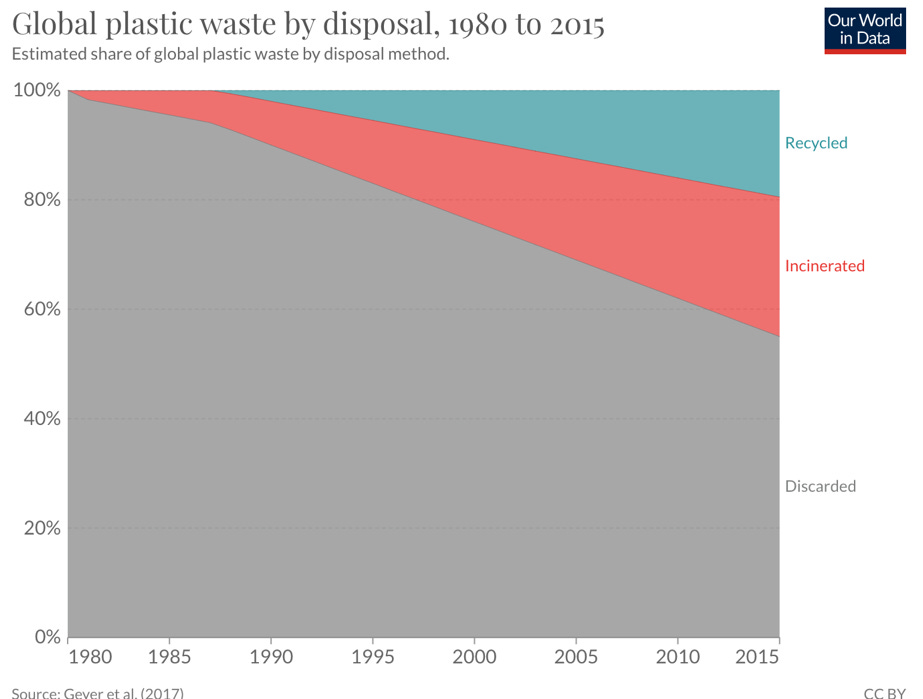

We know that recycling plastic prevents GHG emissions, but most plastics are not recycled. Between 1950 and 2015, 80% of plastic waste ended up in landfills or the environment. While 16% of plastic is recycled worldwide, only about 5% is reused after sorting and processing losses. Plastic additives and contamination are major reasons for the processing losses.

A large portion of plastics is not landfilled, incinerated, or recycled. Instead, plastics are mismanaged through littering or open burning. McKinsey estimates that 19% of all plastics are mismanaged. 8 million tonnes of plastic end up in the ocean each year – that’s equivalent to dumping the contents of one garbage truck every minute. According to the World Economic Forum, plastic packaging makes up over 60% of waste collected from international coastal clean-up operations. Signatories to the UN Environmental Programme’s Global Commitment, representing 20% of global plastic production, reported that less than 2% of their plastic packaging is reusable.

Plastic packaging keeps products fresh and is cheap for manufacturers because they don’t pay any explicit costs for damaging our planet. If they did, the UNEP estimates that the negative externalities from plastic packaging would be $40 billion annually, more than the profits made by the entire plastic packaging industry. If plastic packaging manufacturers had to pay for the cost of pollution, they wouldn’t be in business.

Early research suggests that plastic in the ocean may significantly contribute to indirect GHG emissions. The ocean contains microscopic organisms called plankton that absorb carbon from the atmosphere and store it deep down in the ocean. Our oceans absorb 30-50% of all anthropogenic CO2 emissions. Research suggests that planktons are ingesting microplastics, affecting their metabolism, reproductive success, and mortality rates. In other words, plastics in the ocean could be causing planktons to absorb less CO2, reproduce less and die faster. The indirect result of plastic in the ocean could be the loss of one of the greatest carbon sinks on Earth. Planktons are also food to marine life, and a disruption to their population could affect the entire marine food chain.

Plastics littered on land are just as harmful. Research shows that sunlight and heat cause plastics to degrade and release greenhouse gases. As plastics break down, more surface area is exposed and the rate of greenhouse gas emissions increases.

Net Zero – What Must be True

To eliminate plastics’ greenhouse gas emissions, we need to:

Improve the recyclability of plastics

Use sustainable materials to produce plastic

Use clean electricity to power the manufacturing process

1. Improve the recyclability of plastics

The percentage of recycled plastic has increased over time but remains low.

Recycling plastic faces many challenges. Mechanical recycling is currently the main form of recycling plastic. It involves breaking down plastics into tiny pellets and reheating and shaping them into new plastics. The process requires cleaning the plastics for additives and contaminants. Sometimes, separating the additives and contaminants from the plastic is too difficult, and the plastic is not recycled. Even if the plastic manages to be sorted and cleaned properly, it cannot be recycled indefinitely. Plastics degrade after mechanical recycling such that most plastics are only recycled once or twice. Due to these complications, producers prefer new plastic because of the low cost and guaranteed quality. New recycling methods are being developed that break down plastic back to monomers or feedstock; we refer to these methods as chemical recycling. We’ll discuss some of these advancements in the Solutions section.

2. Use sustainable materials to produce plastic

Plastics don’t need to be made with fossil fuels – they can also be made with bio-based feedstock. Naming conventions may differ, but we will define two types of bio-based alternatives: bio-plastics and bio-polymers. Bio-plastics are chemically identical to fossil fuel-based plastics, except the raw materials used to make them come from sustainable sources such as plants. Bio-plastics eliminate GHG emissions from extracting fossil fuels, but still emit GHGs during manufacturing and post-production from waste management. Bio-plastics are not biodegradable but can be recycled.

Bio-polymers are plastic alternatives that are chemically different from plastics and can be biodegradable. However, not all biodegradable materials can be thrown into your backyard. Some biodegradable materials require specific conditions or equipment achieved in commercial facilities to biodegrade. It’s important to understand the conditions needed for biodegradable materials because manufacturers will purposefully obfuscate the conditions in their advertising to greenwash their products.

Check out page 17 of this case study which shows the real performance of “eco-friendly” products.

3. Use clean electricity to power the manufacturing process

Switching from fossil fuels to renewable electricity is estimated to remove ~50% of the GHG emissions from plastic production -- ‘nuff said.

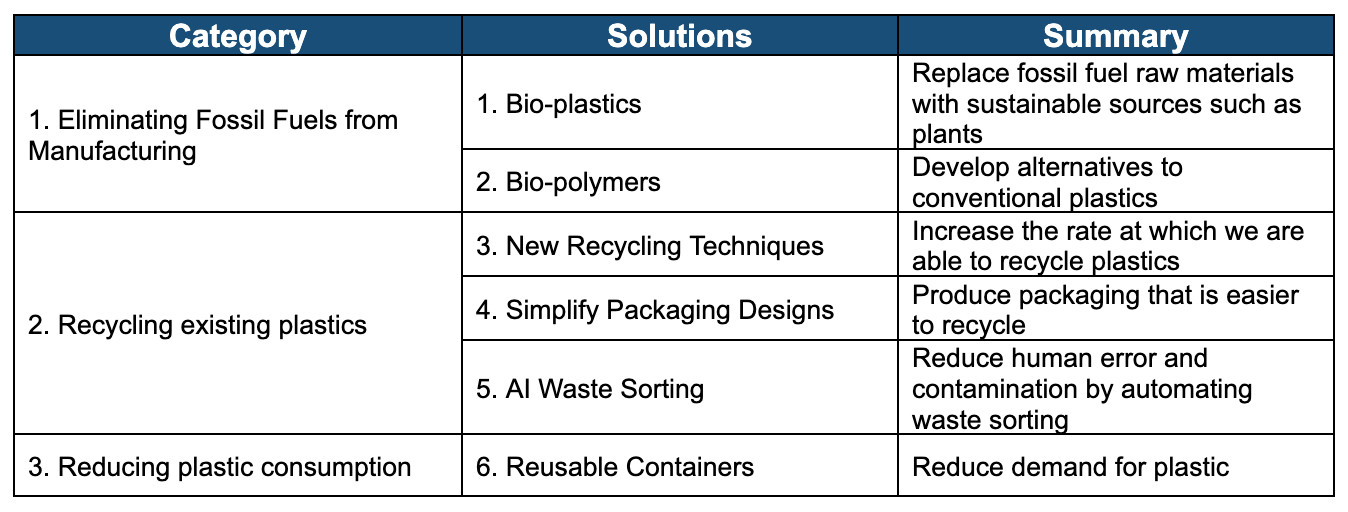

Solutions

Aside from renewable electricity, solutions for a sustainable plastic industry need to focus on:

Eliminating fossil fuels from the manufacturing process

Recycling existing plastics

Reducing plastic consumption

1. Bio-plastics

As previously mentioned, bio-plastics are chemically identical to fossil fuels but use renewable plants, including corn or sugar cane, as feedstock. Bio-plastics need to be combined with other solutions to avoid manufacturing and post-production GHG emissions. To hit net-zero, existing plastic manufacturing processes will need to evolve, and so will waste management systems. Manufacturing emissions can be avoided with carbon capture technology, and post-production emissions can be avoided by recycling. We present bio-plastics as a solution for completeness, but there are fewer requirements to eliminate emissions for bio-polymer solutions.

2. Bio-polymers

Bio-polymers are created with different manufacturing processes and raw materials but are similar to plastics in strength and weight. There are many bio-polymer developments, so we cannot highlight all of them, but we would love to hear about solutions that excite you in the comments.

Notpla

Notpla uses seaweed to replace single-use plastics including water bottles and take-out containers. Their seaweed film is edible and can wrap liquids into packets. In 2019, Notpla handed out liquid packets during a marathon. Water is usually supplied to athletes in paper cups and discarded on the street after hydration. Hours are spent cleaning up the streets after the marathon. With Notpla, athletes popped the hydration packets into their mouths and created zero litter.

Notpla partnered with JustEat to trial its takeout boxes in 2020 and subsequently entered a second trial with more restaurant partners in 2021. Notpla’s takeout boxes are fully backyard-degradable within 30 days. Notpla is planning to lease machines to customers to make their own Notpla packaging in-store.

In 2021, Notpla raised a £10 million Series A financing round led by Horizon Ventures.

Xampla

Inspired by the strength and lightweight of spider webs, Xampla uses plant protein to create plastic alternatives for capsules and food wrappers. The company reassembles plant proteins without making any chemical changes. Xampla partnered with home-recipe delivery company Gousto for packaging the food and condiments in their delivery boxes.

In 2021, the company raised a £6.2m seed round led by Horizon Ventures.

Shellworks

Shellworks uses various sustainable resources to make plastic alternatives, including microorganisms and seafood waste. Beyond packaging, they also produce biodegradable seals and dyes from sustainable resources.

Check out this detailed yet comical video of their process:

According to Crunchbase, Shellworks raised a $820K pre-seed round in 2020 from BoxGroup and Ascension.

BioLutions

BioLutions makes biodegradable single-use products from agricultural waste, including wheat straw, banana stems, and vine stocks. The company can use a variety of agricultural waste, so production is adaptable to the local agricultural system. BioLutions doesn’t use edible agricultural materials, so any impact on the food chain is avoided. In 2019, the company raised €8.3 million Series A financing from Delivery Hero and DEG, among others.

NewLight Technologies

Newlight’s AirCarbon technology combines microorganisms in the ocean with air and GHGs to make biodegradable drinking straws and cutlery. AirCarbon is carbon negative since it removes GHGs from the environment. In 2020, Newlight raised $45 million Series F financing from Valedor Partners and GrayArch Partners.

3. New Recycling Techniques

Below are some examples of novel recycling solutions bypassing the problems inherent in mechanical recycling.

Quantafuel brings various plastics back to their raw material form by heating and purifying the plastic with catalysts. The company’s production plant in Denmark can process 20,000 tonnes of mixed plastic per year. Quantafuel is looking to expand across Europe with more factories.

Carbios uses proprietary enzymes to decompose PET plastics into monomers, enabling 100% plastic recovery. The technology also enables infinite recycling cycles of the same plastic. Carbios is partnering with Indorama Ventures, the world’s largest recycled PET beverage bottle producer, to build its first 100% bio-recycled PET manufacturing plant. The plant is expected to be operational by 2025 and process 50,000 tons per year.

Loop Industries uses proprietary technology to decompose PET plastics and polyester fibers into monomers which are then filtered, purified, and, repolymerized into recycled plastics. The company is currently in the development phase but has multi-year supply agreements with many multi-national companies, including Danone, PepsiCo, L'Occitane, and L’Oreal.

PureCycle uses fluids to extract and filter out contaminants of polypropylene plastic without altering the physical characteristics of the plastic. A combination of solvent, temperature, and pressure is used to bring the plastic back to a near-new form. It’s more effective than mechanical recycling but not as process-intensive as other chemical recycling methods. PureCycle licensed the technology from its original developer, Proctor and Gamble. The first commercial plant is expected to be fully operational by 2023 and have a capacity of 107 million pounds per year.

4. Simplify Packaging Designs

Manufacturers can take numerous steps to reduce their single-use plastic consumption, including: removing unnecessary plastic from the packaging, reducing the variety of ingredients used in the packaging to make recycling easier, and applying the same type of packaging to multiple SKUs to avoid multiple recycling treatment methods.

This video provides a nice visual representation.

5. AI Waste Sorting

Contamination contributes significantly to plastic’s low recycling rate. People are usually not aware of exactly what is and what isn’t recyclable. Some people also deliberately throw food scraps or other non-recyclable materials into trash bins and contaminate the recyclable contents. These problems result in sorting and processing difficulties which make recycling uneconomical. Often, the result is plastic contents being landfilled or incinerated instead. Reducing contaminating materials from recycling bins will ease the sorting and cleaning processes at recycling facilities, increasing the amount of waste recycled.

Waste disposal bins with AI technology can prevent contamination at disposal. CleanRobotics sells AI-powered Trashbots that sort disposed waste into garbage, recycling, or compost bins.

The public and private sectors can purchase TrashBots to sort disposal bins in office buildings and public sidewalks. CleanRobotics raised $5.6 million Series A financing from SOSV.

AMP Robotics is another company looking to improve the recycling process. Their AI machine technology is integrated into commercial recycling facilities to replace the manual human sorting process. The company raised $55 million Series B financing in January 2021 led by XN.

6. Reusable Containers

Reusable containers for everyday purchases like food or toiletries can reduce a significant amount of single-use plastics. Numerous start-ups provide restaurants with reusable take-out containers, including Swapbox, Ozarka, Vytal in Europe and GO Box, Suppli, and DeliverZero in North America. Other companies are providing reusable containers for household items in retail stores. For example, Loop partnered with Kruger and Walgreens to provide groceries and household items in reusable containers. Once customers have used up the contents, they can return the container to the store for it to be washed and reused.

Implementations

The transition to net-zero will require collaboration between the public and private sectors. Here are some initiatives that will move us towards our goal.

Enact more policies restricting plastic use

The rise of plastic regulations is a recent phenomenon, with more than 60 countries introducing bans or levies on single-use plastics over the past 5 years. In 2018, the UN Environmental Programme completed a detailed study of plastics policies across 192 countries. The study found that 127 countries had some form of regulation on plastic bags. Restriction on free retail distribution of plastic bags was the most common, with 83 countries adopting the measure. The second most common regulation, with 61 adoptions, was the ban on manufacturing and importing plastic bags.

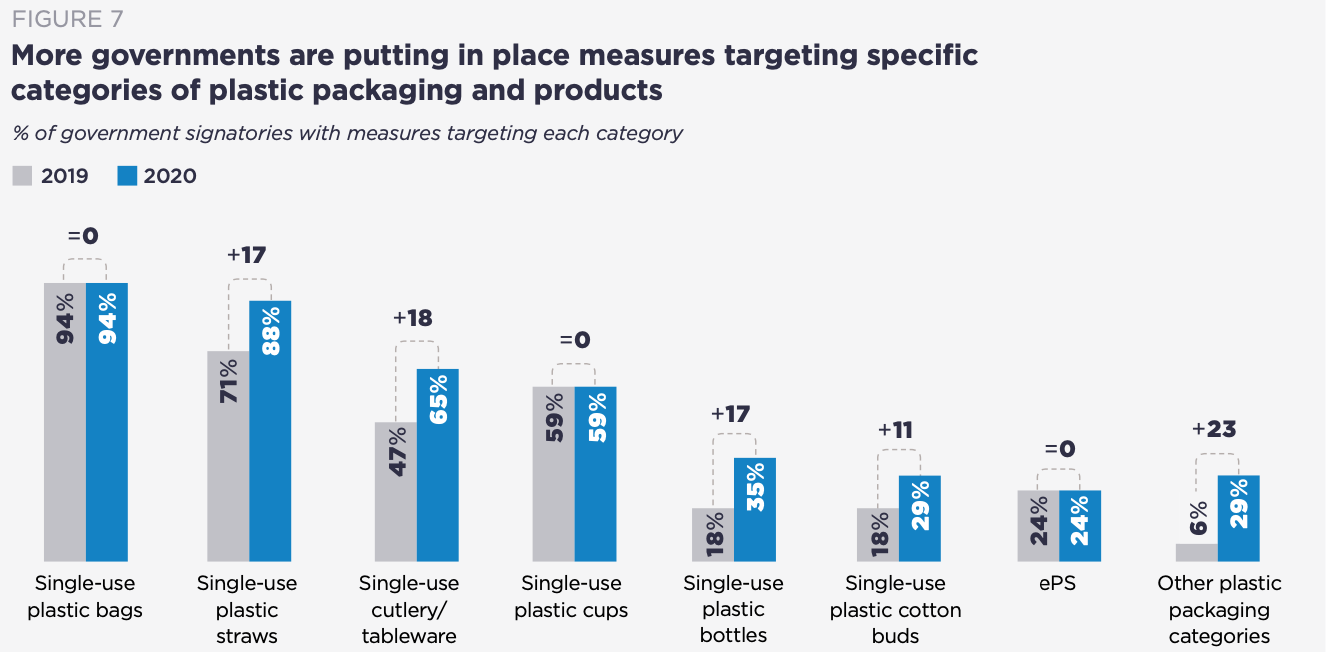

In a separate 2020 survey, the UN Environmental Programme showed that the percentage of government signatories with measures targeting single-use plastic had increased year-over-year and increased significantly in specific categories. Government signatories include the government of France and UK (the full list of the government signatories can be found here).

Further adoptions of easy-to-implement regulations are quick ways to decrease plastic’s environmental impact. For example, a 2016 World Economic Forum industry agenda mentions that US states with container deposit regulations had a recycling rate of 70% compared to the overall US recycling rate of 34%. Michigan’s container deposit rate was the highest at 10 cents, and it has held a ~90% recycling rate for most years. Encouraging more countries to adopt similar regulations will increase the global recycling rate. Understandably, these regulations may require infrastructure investments that lower-income countries may not be able to support. However, these countries can seek international private capital and provide infrastructure investors with government subsidies and carbon credits as incentives.

Manage Waste Domestically

We need to manage our recycling domestically and avoid exporting waste to low-income countries. Historically, many countries sent their plastic waste to China. China implemented a ban on importing plastic waste materials in 2018, forcing countries to find alternative ways of dealing with their waste. Rather than finding domestic solutions, many countries turned to shipping their waste to other countries, including Thailand and Vietnam. However, some of these countries have also begun turning down imported waste.

The rate of waste mismanagement is much higher in lower-income countries. There are also high transportation costs to consider. If we want to solve the emissions problem, high-income countries need to start dealing with waste domestically. “Out of sight, out of mind” is not the solution here.

While costs will be high initially as waste management infrastructure is built and scaled domestically, it’s a necessary investment for a sustainable planet. Developing proper localized waste management systems would be a prudent investment in today's politically turbulent environment.

Investing in automated solutions like AMP Robotics reduces the ongoing capital requirements of recycling by removing human labor inputs. As these technologies become ubiquitous, scale economics suggest that costs will come done. We just need to get the ball rolling.

Better Labelling

In a Harvard Business Review, a study showed that people who used materials they believed would be recycled used more of the materials than people who believed the materials they used would go to waste. As a result of misleading labeling, people are unintentionally creating more waste. There needs to be stricter regulation on package labels. Policies are important because consumers aren’t aware that most of what they put in the recycling bin isn’t being recycled. Intentionally greenwashing products with misleading advertising labels creates more waste than honest labels.

We should push for international alignment on the clarity of labels for recyclable and biodegradable products. Consumers should be able to understand easily how to dispose of their products. Clear labels will also make it easier for AI technology to learn and sort waste at recycling facilities. In most industries, attaining specified thresholds of prediction accuracy is catalytic to AI adoption.

Product designs should also be simplified to make recycling easier. Plastic manufacturers often unnecessarily mix different types of plastics and additives, increasing the risk of contamination during recycling. Policymakers should charge manufacturers more if they use unnecessary additives, such as colorants, or mix various ingredients in the packaging materials. Applying explicit costs to these negative externalities will increase plastics' recycling rate.

Invest in “far out” technologies

We need to allocate more funding towards “far out” technologies – those that have the potential for exponentially more impact and return, even at a higher risk of failure. These technologies include bio-polymers and new recycling techniques. Promoting more and cheaper sources of capital for innovation will encourage more entrepreneurs to join and find solutions.

Price externalities

Increasing the explicit cost of emitting CO2 gives eco-friendly options a competitive cost advantage. Governments can increase plastic pollution costs by taxing the production of fossil-fuel plastics. The tax revenue should be invested in subsidizing renewable plastic alternatives. Policies of this nature will result in reduced green premiums for plastic production, bringing us closer to net-zero.

For some products, this impact may be the difference between reaching commercial scale or failing due to a lack of scalability. According to Material Economics, at a cost of 50 Euros per tonne of CO2, CO2 costs would make up 20% of the price of manufacturing plastics. This brings a significant cost advantage for plastic alternatives and recycling.

In conclusion, while we have a long way to go, we’re making progress. We need to excite entrepreneurial spirits to develop new technologies and convince policymakers to enact these initiatives. Combined, we have a possible way out of our plastic problem.